Diagrams To Build 12 x 4 DIY Shed : See Tips To Make A Shed Effortlessly

Caulking will eventually fail and need maintenance. Make sure corners are right angles, using a carpentry square. A well-built floor will make all difference when it is time to install shed. For fastening, stainless steel nails are the best quality. A poorly constructed foundation will lead to rotting and sagging lumber. Make sure the walls are firmly nailed together at corners. Work with attention and take your time when fitting wall (https://shedconstructionplans.com/12x20-gable-shed-plans-blueprints) frames into place. When they are used to define ceiling of an attic space, they must be placed high enough to provide adequate clearance. Prime and paint the window and let it dry.

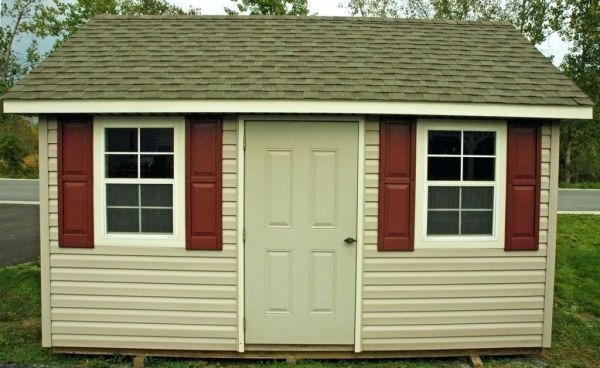

A complete Bill of Materials is listed later on. Just chop the studs 2 ft. longer. One great way to craft spot level is to dig out the grass, loose soil and then tamp it down checking constantly for level. But don't be alarmed if they aren't properly aligned because that rarely happens. Leave these two free so you could manipulate them to match outside edge of the hardwood sheeting as you nail it. This outbuilding has one door and two windows providing you with easy access and plenty of light and ventilation. The green posts are for the front of barn.

Fascia boards vertically attach to eve's on all 4 sides to set up the end point of the roof. A series of precast pier blocks, arranged in three straight rows, provides a simple, secure way to support a floor frame. You can get the job done by yourself in just a few weekends, if you (find) follow our diagrams and invest in quality materials. Snap chalk lines between marks from end to end. If you're building your own roof trusses, handiest place to assemble them is right on the shed floor. Window openings are just like doors but with the addition of a rough sill.

Learn more in-depth instructions for how to install flooring here. This step by step woodworking project is about utility shed drafts. Before breaking ground, you can give a copy of blueprints to a truss representative and receive an estimate of what trusses would cost. Wood screws work better than nails here. The large logs are precut and notched at the mill. We used tar paper underlayment below this with a lot of overlap to help protect from leaks and everything is secured with exterior grade hardware. The main shed has three tilt-in barn-sash windows and a door that's made from the same tongue-and-groove 1 x 6 cedar used for the siding.

We enjoyed making it, and sharing it with all of you. Determine direction that beams install atop the posts on opposite sides of the structure. For example in model it includes a double top and double bottom plate compared to my single top and bottom plates. Note the number of braces to determine the number of blocks needed. This is not essential but it is better for the lifespan of wood. Follow manufacturer's instructions to determine proper water to mix ratio, and how it should be stirred. Mark overhang of last board flush with the face of the frame, and rip board to width.

Install the frame in door opening, using shims and 10d casing nails. We also chose to screw particle board down rather than nail it, to help it resist warping. With the shed site cleared, remove sod and roll out landscape fabric to help keep it clear of weeds. If you want headroom or storage on one side but not the other, the Saltbox is ideal. Plumb the walls and lock them into place with temporarily braces. You can draw a board and use the Protractor key to rotate a line on the end to get your angle. This building took about 40 pallets to complete.

The doors are constructed using the siding cut-outs from ends. A pier shed foundation elevates the shed, keeping it from direct contact with the ground. It provides a stable and level base so doors open, and your outbuilding lasts longer. Including shelving, workbenches, cabinets, toolboxes, and hangers. You may support floor joists, headers, girders, and beams using approved joist hangers. After installing all wooden trusses to the top plates, you need to continue the project by fitting gable ends. Building a generator outbuilding is a straight-forward project, but it would fabricate great value for your property, as it will protect the generator from bad weather.

Before laying sheets, you need to install 1x2s to rafters, as shown in diagram. The skid foundation works well on fairly flat ground, but uneven ground isn't impossible.